Have you ever wondered how your phone screen or solar cells get their super-thin films? One big hero behind the scenes is a piece of equipment called the gas manifold. It’s part of an amazing process called CVD, or Chemical Vapor Deposition.

Table of Contents

TLDR:

The gas manifold in a CVD system controls how different gases are mixed and delivered. It’s like the traffic cop for chemical flow. If it doesn’t work properly, the thin films can end up uneven or useless. Its design and operation are critical for making nano-tech smarter, faster, and cleaner.

What is a CVD System?

CVD systems are used to coat surfaces with thin layers of material. These layers are often just a few atoms thick! It’s widely used in industries like:

- Semiconductors

- Solar energy

- Optics

- Wear-resistant coatings

During the process, gases react or decompose on a heated surface to form thin solid films. But this can’t be done randomly—everything has to be controlled down to the tiniest detail. That’s where the gas manifold comes in.

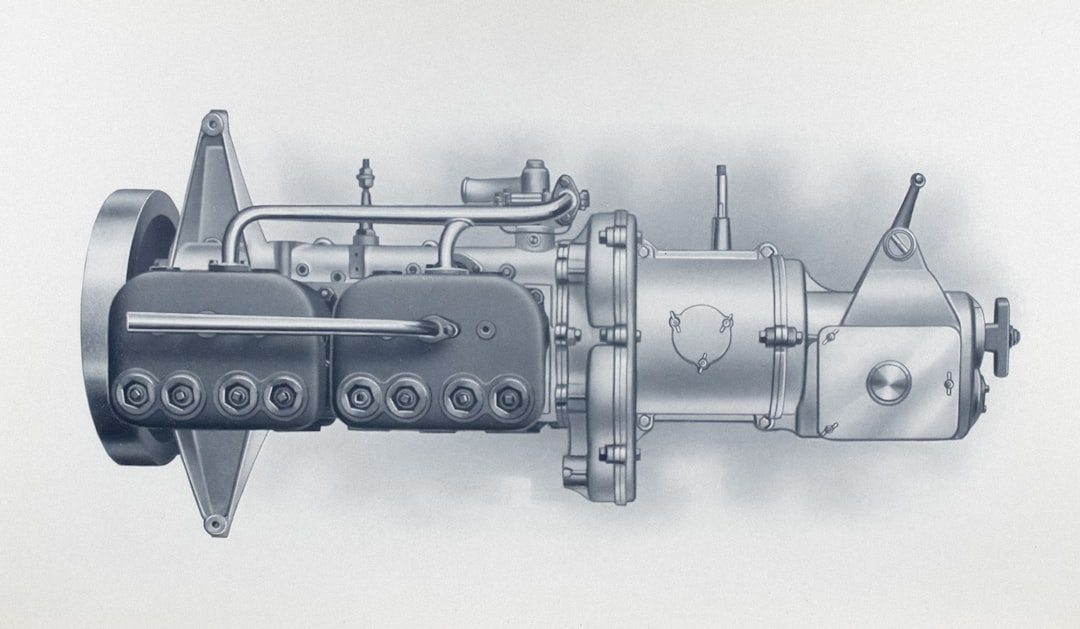

Meet the Gas Manifold

The gas manifold is the heart of the gas delivery system in a CVD setup. Imagine it like a central junction box that directs traffic—only instead of cars, it directs chemical gases!

Each gas travels through its own path in the manifold, regulated by valves and mass flow controllers. These components ensure the gases flow at the right rate, in the right order, and never get mixed up unexpectedly.

Why Is the Gas Manifold So Important?

Okay, so what makes the gas manifold such a big deal? Glad you asked!

Here are some of its critical roles:

- Precision Control: It delivers exact amounts of gas, which is vital for consistent film thickness.

- No Cross-Contamination: The design ensures that gases don’t mix before they’re supposed to.

- Safety: It handles toxic and flammable gases safely—huge plus!

- Quick Switching: Manifolds allow fast switching between different gases, speeding up production.

Inside the Manifold: What’s Really Going On?

Let’s peek inside the manifold to see what it’s made of. It typically includes:

- Mass Flow Controllers (MFCs): These regulate the amount of gas flowing through each line.

- Valves: They open and close the paths for gas flow on demand.

- Purging Lines: Used to clean out gas lines before switching gases.

- Mixing Chamber: In some systems, gases are combined here before entering the reaction chamber.

All of these components work together like a fine-tuned orchestra. One wrong note and—bam!—you could crash the whole film-making process.

Common Gases Used in CVD

CVD uses a variety of gases, depending on the material being deposited. Here are a few examples:

- Silane (SiH₄): For silicon-based films

- Ammonia (NH₃): Common for nitrides

- Hydrogen (H₂): Sometimes used as a carrier gas

- Oxygen (O₂): For oxide films

Each of these gases needs its own line and dedicated flow control in the manifold. That’s because even a small contamination can lead to big problems in nanotechnology.

The “Recipe” for Deposition

Think of thin film deposition like baking a cake. The gas manifold is your ingredient dispenser. Your CVD “recipe” might look like this:

- Step 1: Flow silane at 50 standard cubic centimeters per minute (sccm)

- Step 2: Add ammonia at 100 sccm

- Step 3: Heat the substrate to 600°C

- Step 4: Hold for 15 minutes

If the manifold doesn’t deliver the gases at exactly the right time and amount, guess what happens? Your cake burns—or in this case, your thin film fails.

Smart Manifold Design: Things to Consider

Designing a good manifold isn’t just “plug and play.” Engineers have to think about a lot:

- Material compatibility – Some gases are corrosive

- Distance from gas source to chamber – Too long, and delays can occur

- Leak tightness – A single leak can throw off the whole process

- Thermal management – Some gases need to be preheated

Choosing the wrong design can mean poor film quality, lower yields, or even safety hazards.

Image not found in postmetaCleaning and Maintenance

Like any hardworking system, the gas manifold needs some TLC (tender loving care). Here are some best practices:

- Regular Leak Checks: Make sure fittings are sealed

- Purge Unused Lines: Use inert gases like nitrogen

- Calibrate Flow Controllers: Keeps accuracy in check

Skipping maintenance can lead to contamination, which ruins thin films faster than you can say “nanometer.”

Future Trends

Gas manifolds are already impressively smart. But things are getting even cooler. Here’s what’s coming next:

- AI-Controlled Systems: To optimize gas flow in real-time

- Smaller Footprint Designs: For compact labs and mobile setups

- Sustainable Materials: Less waste, more recycling

All these upgrades mean better thin films for electronics, solar panels, and super-advanced tech that’s easier on the planet.

In Summary

The gas manifold is the unsung genius inside a CVD system. It manages flows, prevents mix-ups, and keeps the deposition process ultra-precise. Without it, the thin films we rely on wouldn’t exist—or they’d be way worse.

So next time you use your phone or admire a solar panel, thank the gas manifold. It may be hidden in a lab, but it’s helping power the future!