Plastic injection molding is the perfect manufacturing process for producing various computer parts. This extremely versatile method of producing tiny plastic parts and products is preferred for manufacturing computer parts because it offers multiple advantages over other plastic molding methods.

Not only is plastic injection molding more straightforward and more reliable, but it’s also highly efficient compared to other molding techniques. But we’ll get to the top advantages of this manufacturing technique in no time.

Nevertheless, when selecting a plastic injection molding partner to work with for your project, keep in mind that you need to go with a reliable company that will uphold the best standards for both quality and quantity to meet your demands and timeframe.

Below, we’ll go through the biggest perks of plastic injection molding for the production of computer components and why you should select this production method before any other.

Table of Contents

Plastic Injection Molding Can Produce Computer Parts With Detailed Features and Surface Quality

Utilizing plastic injection molding means that you’ll get highly optimized products at the end regardless of whether you need a pretty simple part for your computer production unit or a piece that requires the most detailed features and a complex structure.

If you’re from the industry, you already know that plastic computer parts are made to uphold specific standards of functionality and design that most plastic injection molding services will be more than happy to accommodate.

For example, informational technology equipment, or ITE parts, must have an outstanding capability to withstand pressure, and plastic injection molding offers just that.

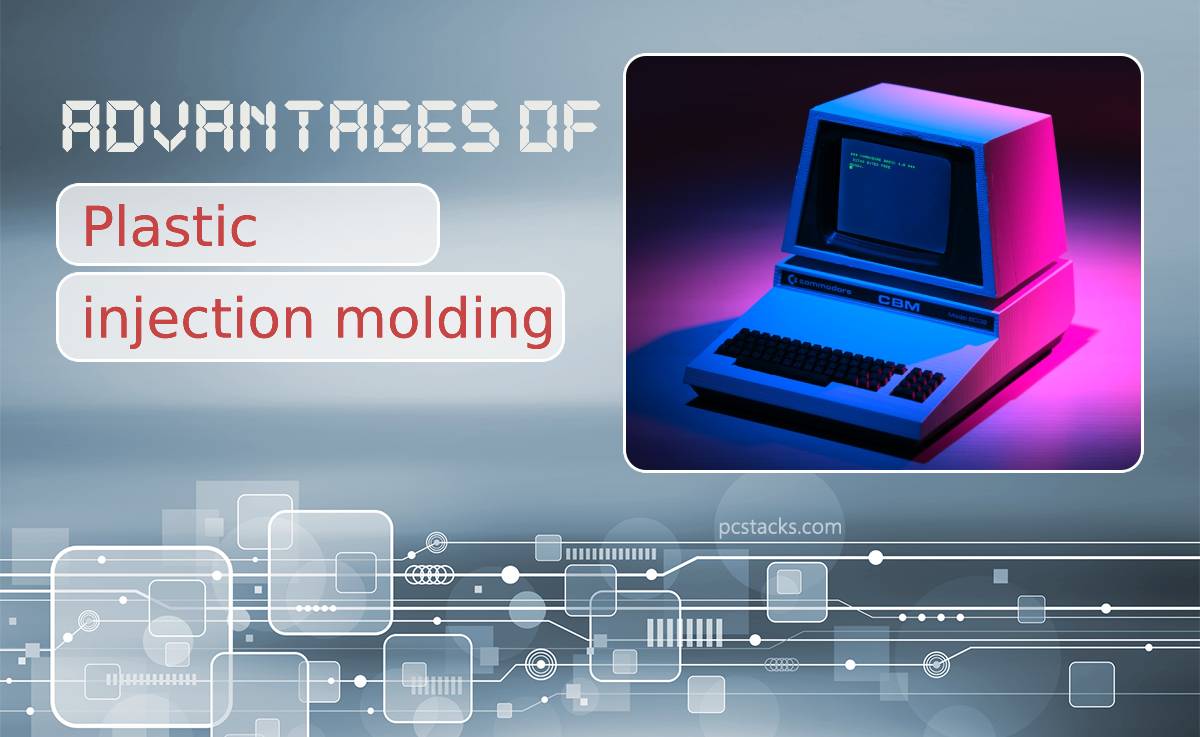

Accurate Design

Computer parts and components can come in many designs and forms. It doesn’t matter if we’re speaking about central processing units, a mouse, or a monitor; they all must be manufactured with incredible versatility and accurate design.

Whether or not the final piece’s surface should involve the effect of a product that’s mirror polished, brushed polished, glossy, or matte, plastic injection molding can answer to create the most complex and accurate designs of computer parts.

Plastic Injection Molding Is a Highly Efficient Manufacturing Method

Once you get the injection molds designed according to your specification and the presses get pre-programmed, the actual plastic injection molding process is swift compared to other similar molding methods.

Besides, from a single mold, you can produce millions of units which makes the high production output rate incredibly efficient and cost-effective.

Enhanced Durability and Strength

While the digital age we live in has increased the worldwide demand for computer parts, it has also increased the need for durability and strength of these components to survive longer and provide long-term satisfaction for the end-user.

In plastic injection molding, it’s possible to use fillers in the injection molds to reduce the density of the plastic material. In contrast, it’s molded and adds greater strength to the part after the process is finished.

In fields like information technology equipment, where parts need to be durable and extra strong, plastic injection molding is way better than all other plastic molding techniques.

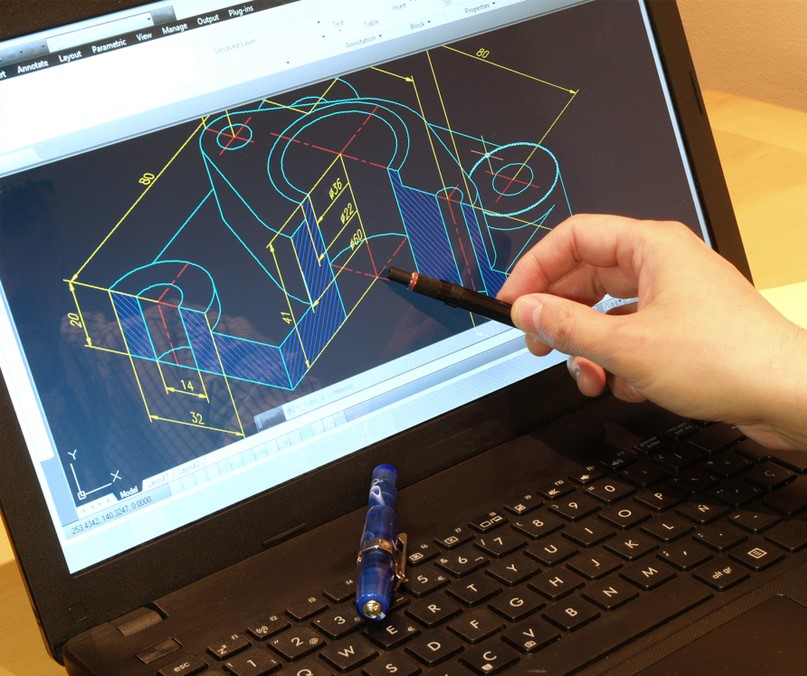

Ability to Use Different Plastic Material Types at the Same Time

Another advantage of utilizing plastic injection molding for manufacturing computer parts is using different types of plastic material simultaneously. This is possible with co-injection molding, which eliminates the need to use a specific kind of plastic.

The leading plastic materials utilized for making computer parts and consumer electronics include high-impact polystyrene (HIPS), acrylonitrile butadiene styrene (ABS), and expanded polystyrene (EPS).

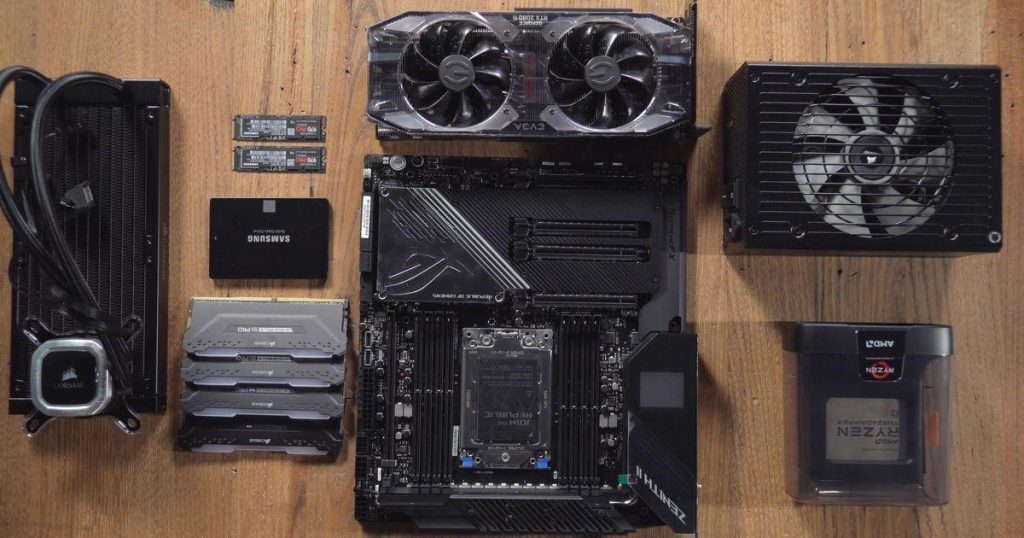

Process Automation to Save Further Manufacturing Costs

If you decide to work with a trustworthy manufacturing service, the chances are that their injection molding process is fully automated. This way, most tasks are performed by machines and robotics that a sole human operator can control and manage.

As a result, automation helps to reduce manufacturing costs further, as the overheads are significantly lower. With a reduced human workforce, the manufacturer’s overall price is reduced, which is usually passed on to the final customer.

Final Words

When you know the most significant advantages of plastic injection molding for the production of computer parts, you can establish a partnership with a reliable molding company.

However, take your time and do your research before you sign any contracts to produce your needed parts. Nevertheless, with the right design and intent in functionality, your project will be a success in no time.